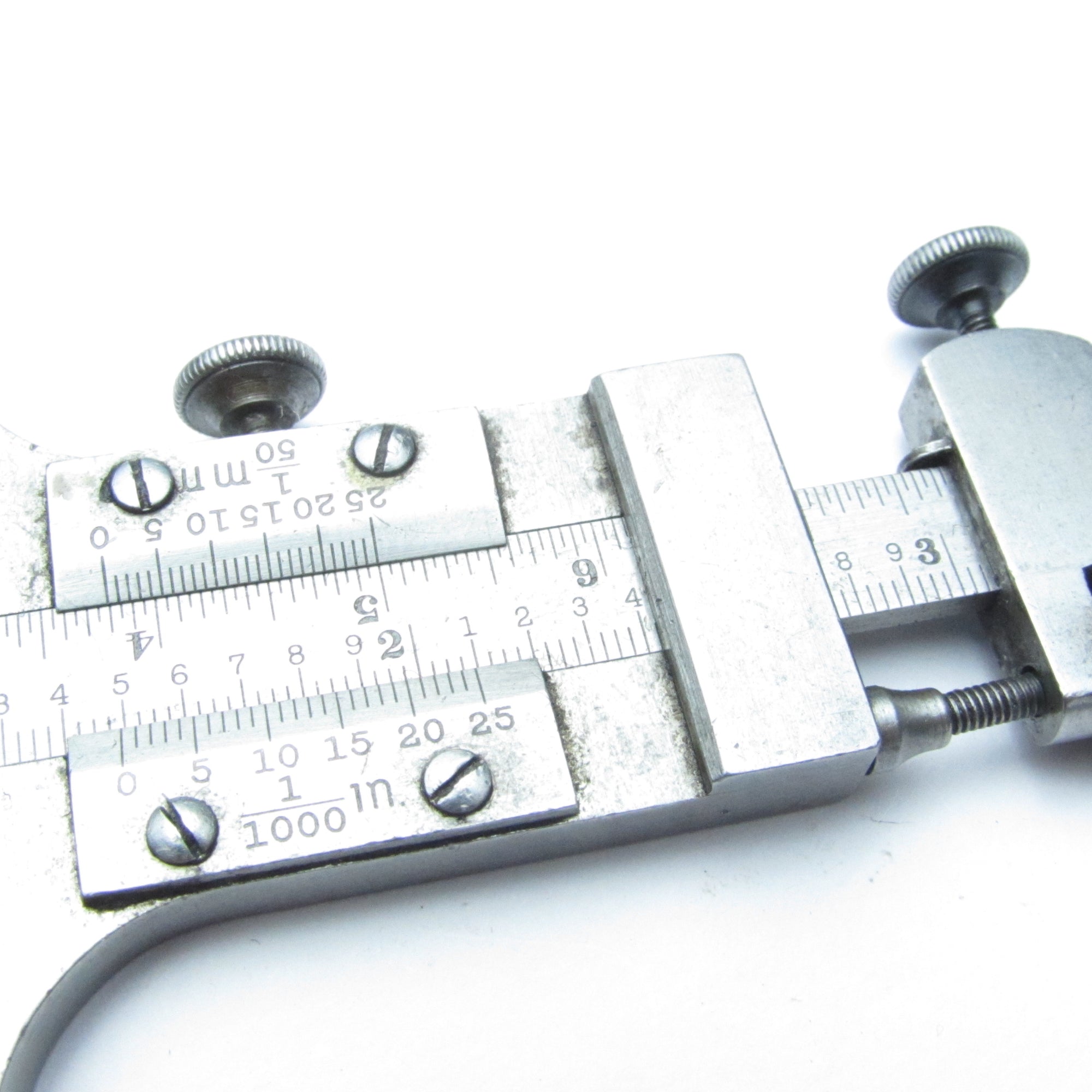

I suspect the truth is that ALL primers vary somewhat in diameter, depending on the lot, due to the wear-use of the cup-forming dies. That info was published (along with a bunch of other info about modern rifle primers) in Chapter 3 of the first BIG BOOK OF GUN GACK. Only had one kind of Federal Small Rifle primer was measured, the 205 Match-which ranked the second-smallest in diameter of the 10 primers. One lot of Federal 215s was the largest in diameter-but Federal 210 and 215 Match primers were on the small end of the diameter-spread. Measured 11 brands/types of Federal, Remington and Winchester Large Rifle primers, with a digital Starrett micrometer, all that the same temperature. Could find NO consistent difference in large rifle and small rifle primers of various American brands-and in some instances different manufacturing lots of the same brand averaged smaller or larger in diameter. I'd heard all sorts of things about primer dimensions over the years, and a few years ago decided to measure a bunch to see what was up. 0005 larger in diameter than other brands IIRC.ĭunno about that statement concerning Federal primers. This may also be due to my use of Federal LR primers which are. I've been using more Norma and Nosler brass in the last few years and these brands seem to have issues when trying to seat primers deep enough. I've made primer pocket reaming part of my standard prep for new brass. I suggest you uniform the pockets to the correct depth before firing another round. He threw all the brass, bought new Winchester 30-06 brass and went happily forward. In with the Federals again and now they were about. Pushed the Federals out and used my carbide large primer uniformer on the primer pockets until it quit cutting. But they were still way above the case head. I had some Federal 210's in my range box and pressed those in with my hand primer tool.felt fine. I took a couple loaded rounds over my bench, pulled the bullets, dumped the powder and pushed the live primers out.

He said they had gone in fine, using the priming tool on his Rock Chucker. 010 above the case head.a little hard to do but that was in the ball park. With my dial caliper, I measured them at about. All of the primers were far enough above the case head that you easily catch them with your fingernail.

If the lugs had cleared the lug abutments in the receiver, he would have caught the bolt right between the eyes.Īfter everything settled down, I took a look at his reloads. He was damn lucky the bolt had j-u-s-t started to rotate when it went off. He started to open the bolt and BAM.it went off! I watched as he chambered a round and it looked like it was pretty snug when he closed the bolt. He mentioned to me that he was having trouble closing the bolt on his reloads and asked if I'd take a look at it. That's a damn dangerous situation.I saw what can happen first hand.Ī guy two benches down from me was working with his 30-06 Model 70 hunting gun. I wonder how thick the brass web will be after adjusting the pocket depth & if it will matter? It seems like decent enough brass, but is it really worth all the dicking around to be reloadable? Mine sits in the scrap brass bucket waiting to be recycled. The Hart tool is adjustable, the Whitetail tool is not. 010-.015" deeper to reach flush or a touch of recess. If your primers aren't tight going in, maybe a depth uniformer alone will work for you. I'm just not that desperate or interested in wasting more time or $$ on this brass. Mine broke years ago & hasn't been replaced. You could possibly uniform the pockets deeper, but the tool doesn't change the diameter enough for easy seating in the 2 or 3 cases I've tried with an old Hart depth uniforming tool & also a Whitetail carbide tool. Situation normal with all the S&B rifle brass that I've seen lacking in diameter & depth. I cant say for sure about premature ignition with a high primer in a bolt gun, but it doesn't seem like an optimal condition.

0 kommentar(er)

0 kommentar(er)